Add meg itt a címsor szövegét

It is important for all manufacturing companies to have a clear understanding of their production parameters. With access to machine operating data, it is easy to identify bottlenecks, optimize production, detect unnecessary downtime, and reduce scrap rates.

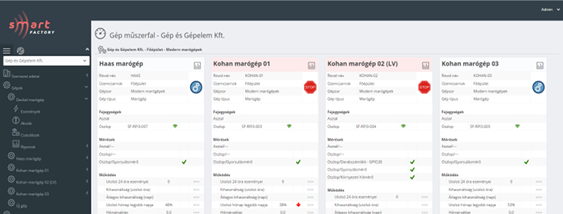

SmartFactory is a comprehensive production monitoring solution developed and refined by us, which measures, displays, and analyzes the specific characteristics of production machines and processes, and, if necessary, sends notifications and alerts about detected events.

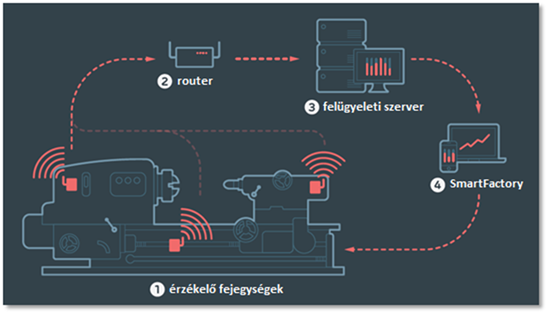

Outline system structure:

1. Multifunctional measuring heads installed on the machines measure the physical characteristics of machine operation. The collected data is transmitted to the data collection center via radio connection.

2. The data collection center located on the plant site collects the data and transmits it to the monitoring server via a computer network.

3. A felügyeleti szerver a megkapott adatokat tárolja, monitorozza, feldolgozza, elemzi és megjeleníti. Szükség esetén SMS vagy email útján értesítést, riasztást küld az érintetteknek (pl. gép leállás).

4. Az adatokat és kimutatásokat számítógépen, táblagépen vagy okos telefonon akár távolról is elérheti az erre jogosult felhasználó.

Areas of application:

- Monitoring of production processes, piece counting, production volumes, scrap rates

- Machine efficiency reports, production times, downtimes, planned and unplanned machine stoppages

- Maintenance records, machine logbook management

- Tool utilization, maintenance cycles, tool card management

- Maintenance support (daily, weekly, monthly maintenance indicators)

- Quality control of production processes (SPC)

- Measurement system analysis (R&R study)

- Machine performance test

- Calculation of process capability index

- Production performance reports (Yield, PPM)